Gas Storage Membranes

Hydroflux has partnered with Baur Folien GmbH based in Germany, a market leader and specialists in the selection, design, supply, manufacture, and installation of high-quality gas storage equipment to maximise the product reliability whilst reducing the project lifecycle costs.

Baur Folien GmbH has been providing customers with customised solutions for over 30 years with a record of up to 9.000 successfully implemented projects worldwide.

Biogas Storage Systems Suitable for:

- Biowaste

- Food Waste

- OFMSW AD (Organic Fraction of Municipal Solid Waste)

- Sewage gas for industrial WWTP

- Landfill gas

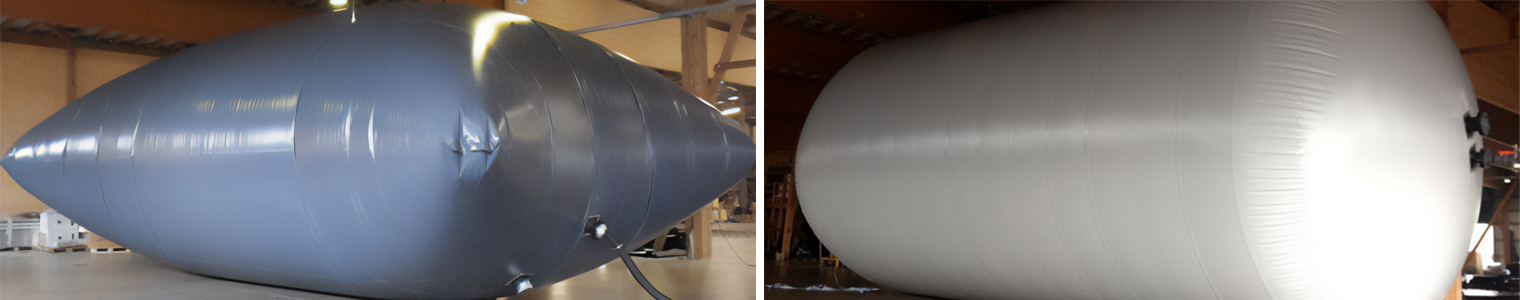

Double Membrane Gas Storage

For the storage of biogas, double membrane gas storage can be installed on both in-situ concrete, precast, or suitable steel tanks. The external weather protection membrane serves to protect the internal gas membrane from the effects of the weather.

The gas storage membrane is flexible and varies according to the amount of gas produced. The shape and color of these gas storage covers can be customized according to the requirement and customer’s request.

Find out more

Gas storage for Industry and Sewage Treatment Plants

Double membrane gas storage system is the state of the art in biogas storage. A system that is extremely robust and durable and able to store variable amounts of gas at a constant pressure.

The outer weather protection foil keeps the wind and rain away from the integrated inner gas storage foil. This protects the gas storage membrane to ensure a long service life. High-quality materials provide high chemical resistance and minimal diffusion rate, even at higher operating pressures.

Gas membrane materials

Selecting the correct material for gas storage membranes is vital. Anaerobic digestion of sewage sludges, food waste and industrial waste can produce very high levels of H2S and other contaminants such as VOCs.

We can offer membrane materials suitable of storing biogas at 2,000ppm to >20,000ppm of H2S or high levels of VOCs, without compromising the life expectancy of the materials.

Examples of material degradation due to incompatibility of membrane materials with gas impurities or high H2S levels:

Hardening in PVC coated fabric, resulting in cracking of PES fibres

Breakdown of PVC coated fabric

External gas storage system

The installation of the double membrane gas storage system does not necessarily have to be done on a tank. The gas storage can also be mounted on a floor slab, concrete slab or on a ring foundation made of concrete with an earth foundation.

The design (square, round, oval) and height can be customized according to requirements or desired volume.

A simple and robust solution is also unpressurised gas storage in single skin membranes. This type of gas storage can be installed inside protective housings such as existing tanks, building or other structures. The external structure is used as protection and suspension for the pressure less membrane and provides a solution where very high wind resistance is required.

Gas storage bags can be manufactured in many sizes and shapes, e.g., as cushion, cylinder or quad storage to the dimensions required for your project.

High-quality, long-lasting membrane materials guarantees maximum robustness.

Single layer cover, gas-tight

A simple and effective solution for capturing gas and odor emissions is the single layer gas-tight tank cover.

The structure is braced directly above the tank with a center post. This variant is suitable only for vessels that do not require flexible gas storage.

Flexibilization and upgrades

Upgrading an existing gas storage tank or lagoon solution with a new cover can provide additional flexibility and capacity and contain odors.

Retrofitting an existing tank or CAL with a double membrane storage system can offer much larger gas storage volumes whilst protecting the gas storage membrane from wind, rain and UV.

Before and after upgrade, from 420m3 to 1840m3 of gas storage

Covered anaerobic lagoons – CAL with double membrane gas storage