Biogas Flares

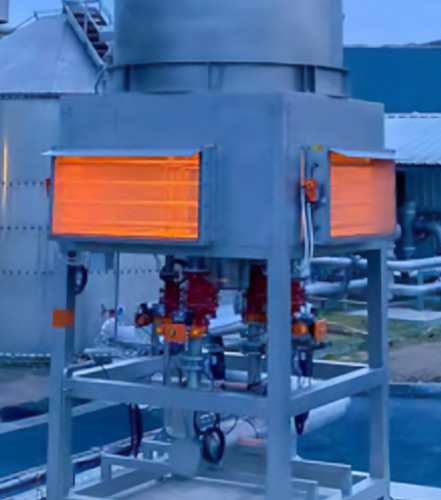

Medium-temperature Biogas Flare, MTU Series

The MTU series Biogas Flare is an enclosed, natural draught flare for the safe and efficient combustion of biogas, sewage gas or landfill gas. They have been developed by Gastechnik Himmel GmbH as a specialized supplier for flares and gas handling equipment and are tried tested and proven in hundreds of applications worldwide.

Typical of deployments:

- Thermal disposal of combustible surplus gases such as in biogas, sewage and landfill gas plants.

- Various special gases

The MTU series flares are available in various sizes for a gas throughput of 50-3000 Nm3/h. If a higher gas throughput or combustion of special gases is required, a special flare system or combined modules can be offered.

All control functions are housed in a weatherproof and ready-to-connect control cabinet. All gas pipework is made of stainless steel 316 that is welded, blasted, and passivated. The support structure and flare shroud are made from 304 grade stainless steel.

As soon as the start command and the required gas inlet pressure to the flare are present the flare burner starts. The automatic gas burner controls the electrical ignition process automatically and monitors the flame during operation.

The main features of a typical system are as follows:

- Safe, reliable, and efficient combustion over the entire defined operating range

- Continuity of the flare flame under severe weather conditions

- Safe and reliable ignition system with a high-capacity LPG pilot

- SS flame arrestor with temperature interlock

- Dedicated burner controller with gas pressure monitoring and flame supervision, suitable for continuous operation

- Concealed and homogenous burning at minimum 760-850 oC

- Dwell time 0.6 seconds

- Automated re-ignition after flame failure with purge timer and lockout after multiple start attempts

- Low-noise design

- Low-maintenance operation

- Flame tube and base frame made of stainless steel

- Thermal insulation for protection of the flame tube from over temperature

Find out more

Several upgrade options are available for the MTU series flares. The most common are listed below. Others can be considered at request.

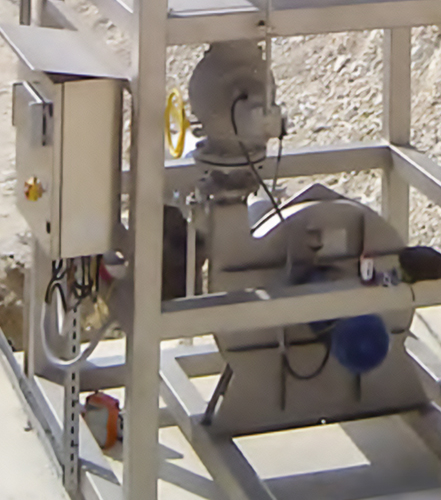

- SS Biogas blower (ATEX certified non-sparking) with IECEx Motor and VSD

- Gas Quality supervision CH4 or CH4/O2 (if not provided by site)

- Gas Flow Monitoring

- PLC with HMI

- Thermocouple for combustion temperature measurement with display

- Control Enclosure in SS

- Sunroof for Control enclosure

- Remote Mounted Control Panel

- SS panels around base flame, with access door for maintenance

- Upgrade to 1000degC combustion with temperature regulation

- Condensate KO Pot at inlet

- Anchor set for installation

- Spare parts kit

The MTU series flares are available in several sizes and capacities. The typical flow and thermal capacity as shown below is for typical biogas CH4 concentrations. All values need to be confirmed, based on the site gas conditions.

“What CH4 content can be combusted in flares?”

The combustion system can be designed for gases low, medium or high CH4 contents, ranging from ~35% to >95% CH4. Special flares or lean gas treatment thermal oxidisers are available to treat low calorific off-gases.

“What minimum distances need to be observed?”

The enclosed combustion chamber ensures the thermal ground radiation is safe for operators to access the flare control panel. As a guide, the following distances should be observed. (Check relevant Australian Standards for confirmation).

- 3 meters to other adjacent equipment. Also to roadways and boundary lines if the flare is fenced.

- 7.5 meters to roadways of boundary lines if not fenced.

- 15 meters from the perimeter of a digester or other potential large source of release of combustible gas

“Does the gas need to be pre-treated?”

The gas supply needs to include a condensate collection system to collect and drain free water and coarse filtration such as a condensate pot.

“Does air ingress into the flare gas supply stream matter?”

The gas must be supplied at a composition that is safe to handle and reliable to combust. If there is an opportunity for air ingress into the gas supply, it must be monitored and interlocked to ensure safe combustion.

“Can flares operate at variable flow rates?”

The smaller model MTU 100 to MTU400 flares have been designed to operate at a fixed flow rate, depending on gas supply pressure. The flares models from MTU600 upwards have additional multi stage burner to allow operation over a broader operating range, whilst ensuring safe and reliable combustion.

“Are MTU series flares suitable for Australian Requirements?”

The MTU series flares have been designed to EN standards but upgraded to also meet Australian Requirements.

“Do flares need to be fenced?”

Australian Regulations require flares which are accessible to the public or unauthorised personnel to be fenced.