Spiral Screens

Compact Screening Solutions for Smaller Applications

The HUBER ROTAMAT® Ro9 spiral screen is a compact and versatile solution for small wastewater treatment plants with capacities of up to 5 ML/day. This all-in-one unit efficiently performs screening, washing, compaction, and dewatering in a single, space-saving design. The Ro9 spiral screen effectively removes solids to protect downstream processes, reduce maintenance, and ensure reliable plant performance. Its robust construction, combined with automatic self-cleaning, makes it an ideal choice for municipalities and councils seeking a low-maintenance and cost-effective screening solution.

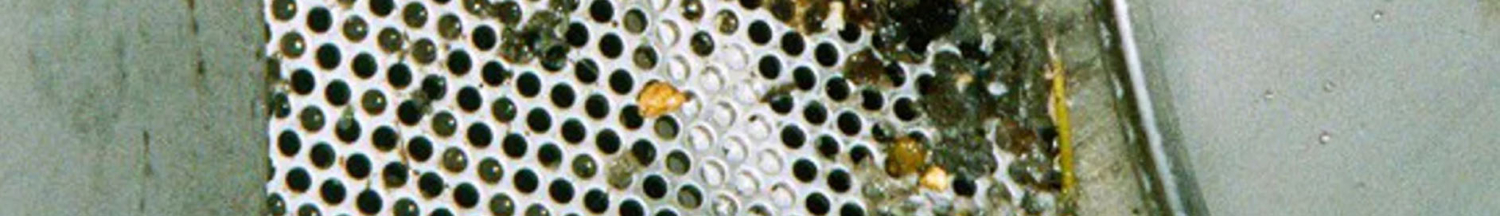

The screening elements are available with either wedge wire bars, spaced from 0.5 to 6 mm, or perforated plate with apertures ranging from 1 to 6 mm. By selecting the appropriate aperture size and screen basket diameter—available in sizes up to 700 mm diameter—throughput can be precisely adjusted to meet specific site requirements. The screen can be installed directly within a channel or in a separate tank, providing flexible installation options to suit various plant configurations.

Benefits of the HUBER ROTAMAT Ro9 spiral screen

- Proven design: Over 4000 spiral screen installations globally

- Cost-Effective Investment: Low capital expenditure with long-term operational savings

- Simplified Installation: Quick and straightforward setup, even for retrofit applications

- Reliable Self-Cleaning: Stainless steel screw flights and durable, wear-resistant brushes ensure consistent performance

- Durable Construction: All-stainless steel design for extended lifespan with minimal maintenance

- Odour-Free Operation: Fully encapsulated system prevents unpleasant odours

- Reduced Disposal Costs: Integrated screenings washing and compaction minimise waste volume

Screen Operation

As wastewater flows through the open front end of the spiral screen basket, solids are retained by the screen bars or perforations, with the separation of floating, settling, and suspended solids depending on the selected bar spacing or perforation size. As the screen surface becomes blinded with solids, an additional filtering effect is created, allowing smaller particles to be captured.

The system automatically starts operation when the upstream water level rises due to surface blinding when a robust stainless steel screw efficiently removes the retained solids from the screen basket. Wear-resistant brushes attached to the screw flights provide additional cleaning as the screw conveyor transports the screenings through a sealed, inclined pipe.

During transport, the screw conveyor dewaters and compacts the screenings, reducing volume and odours before discharging the material into the customer’s container or subsequent conveying system.

The HUBER Micro Strainer ROTAMAT® Ro9 spiral screen is constructed entirely from stainless steel and undergoes acid treatment in a pickling bath for long-term durability. It can be installed directly in a channel or within a separate tank.

From Concept to Completion – Contact Hydroflux Epco for Tailored Screening Solutions

Effective screening is essential for wastewater treatment, protecting downstream processes and enhancing plant performance. Hydroflux Epco provides customised screening solutions, working closely with clients to develop efficient designs that integrate seamlessly into existing facilities.

Our expert team delivers comprehensive design documentation and ensures optimal handling, storage, and disposal of screened material for compliance and efficiency. With deep technical expertise, we guide clients in selecting and optimising the right screening systems for their needs.

Contact Hydroflux Epco today to learn how our high-performance solutions can streamline your wastewater treatment operations.

HUBER ROTAMAT Ro9 Spiral Screen Brochure

Please download the HUBER ROTAMAT Ro9 Screen brochure here.