Multi-Rake Bar Screens – RakeMax®

RakeMax® Course Screen

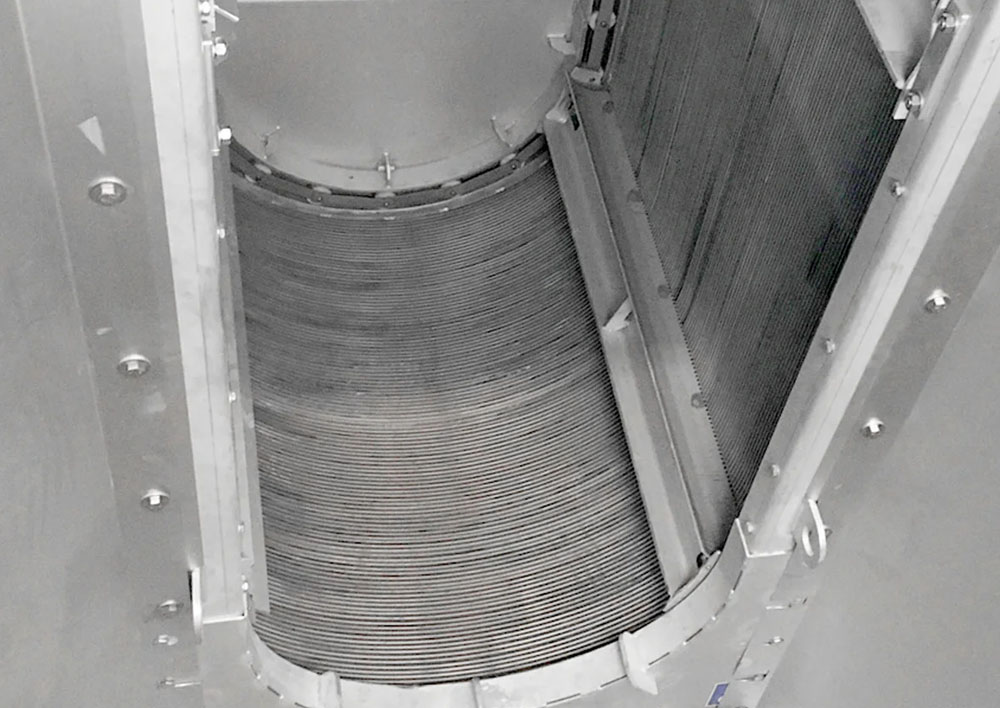

HUBER’s RakeMax Bar Screen is a heavy duty course screen designed to process wastewater with high levels of solids and/or gross material. The screening medium is effectively a row of bars that can be spaced from 6 mm to 50 mm in channels up to 4 m width to suit specific requirements. Channel depths of up to 20 m are possible with the RakeMax Course Screen. A rake system is used to clear the bars of screened material and transport the screenings to a discharge chute using a specially designed wiper that ensures that the bars are properly cleared.

The course screen is inclined at 75 degrees which is the ideal installation angle to allow the effective removal of a variety of solids from small twigs to trash and logs.

- Channel width; 500 mm – 4000 mm

- Capacity: up to 3000 L/s subject to wastewater quality

- Discharge height above channel floor; 2.2 m to 20 m

- Bar spacing: 6 – 50 mm

- Installation angle: 70 – 85 degrees

Benefits of the RakeMax Course Screen

- Easy-to-retrofit into existing channels, installation without channel recesses possible

- Completely odour-encased screen with easy to remove covers

- Compact design with a low installation height above ground level

- Simple and easy-to-access chain tensioning unit

- All parts in contact with medium (except the chain, drive and bearing) are made of immersion pickled stainless steel. (Optional stainless steel chains available).

- Very low head loss with high separation efficiency

- High screenings discharge capacity through adjustable cleaning elements

- Screen installation is possible without a bottom step

- The screen consists of a self-supporting folded stainless steel profile so that it can easily be lifted out of the channel.

- Not hindered by gravel or grit

- Defined meshing of the cleaning rakes with the bar rack ensures a high operating reliability.

- Independently replaceable rake and comb plates

General Operation

The RakeMax Screen features a compact design with a low installation height above the floor. Even in deep channels, its height is determined only by the placement of the downstream screenings transport or washing system, making it a space-efficient solution.

The cleaning elements are securely attached to drive chains at both ends, with each chain powered by a sprocket on a common shaft and a flange-mounted gear motor. The precise meshing of the cleaning rakes with the bar rack ensures reliable operation and effective debris removal.

To prevent damage and ensure uninterrupted performance, the system is equipped with an electro-mechanical overload protection mechanism. This spring assembly with deflection monitoring automatically halts operation if a blockage occurs or when the preset load limit is reached.

Model Variants and Options

RakeMax® HF

The RakeMax HF excellently combines the advantages of the well-proven RakeMax with the positive properties of a screen with a bar rack that is installed with only a small inclination. The RakeMax HF has a L-shaped design with two different screen sections: The flat bottom section provides a large screening surface and favourable hydraulic conditions, the steep conveying section ensures screening on a small footprint. Due to the extremely flat installation of the bar rack of 30° the screen section through which the flow passes is always double the depth of the approaching flow. Material removal from the screen starts virtually right at the bar rack mounted flat to the channel bottom so that any accumulation of disturbing material is eliminated. The optimal approaching flow conditions and large effective bar rack surface ensure a high hydraulic throughput capacity.

RakeMax® CF

The HUBER RakeMax CF features a U-shaped stationary bar rack positioned between two screen frames, aligned with the wastewater flow. Wastewater enters through the open front side of the screen and exits through both the left and right sections of the bar rack, while solids are retained on the inner surface of the U-shaped rack.

As solids accumulate, they gradually blind the bar rack surface, affecting the water level in the channel. To maintain efficiency, cleaning is automatically triggered once the upstream water level reaches a set point. The RakeMax CF achieves this using its cleaning elements, which are attached to a chain system. The number of these elements can be adjusted, allowing the discharge capacity to be tailored to specific requirements.

With its compact design, the RakeMax CF has a low installation height above the floor. Even in deep channels, its height is determined only by the placement of downstream screenings transport or washing systems, making it a flexible and space-efficient solution.

Safety Vision

The innovative HUBER Detection System Safety Vision enables the screen to “see” the screenings and reliably identify potentially critical contaminants. This effective protection mechanism reliably prevents damage to the screen or the downstream equipment, which not only increases the availability of the machines involved, but also improves the operational safety of the entire plant technology. In addition, the adaptive operation based on event detection means that the machine can always be optimally utilised and the running time of downstream machines can be optimised according to the actually necessary demand.

From Concept to Completion – Contact Hydroflux Epco for Tailored Screening Solutions

Effective screening is essential for wastewater treatment, protecting downstream processes and enhancing plant performance. Hydroflux Epco provides customised screening solutions, working closely with clients to develop efficient designs that integrate seamlessly into existing facilities.

Our expert team delivers comprehensive design documentation and ensures optimal handling, storage, and disposal of screened material for compliance and efficiency. With deep technical expertise, we guide clients in selecting and optimising the right screening systems for their needs.

Contact Hydroflux Epco today to learn how our high-performance solutions can streamline your wastewater treatment operations.

HUBER RakeMax Screen Brochure

Please download the HUBER RakeMax Screen brochure here.