Packaged Inlet Works

Reliable Packaged Inlet Works Systems

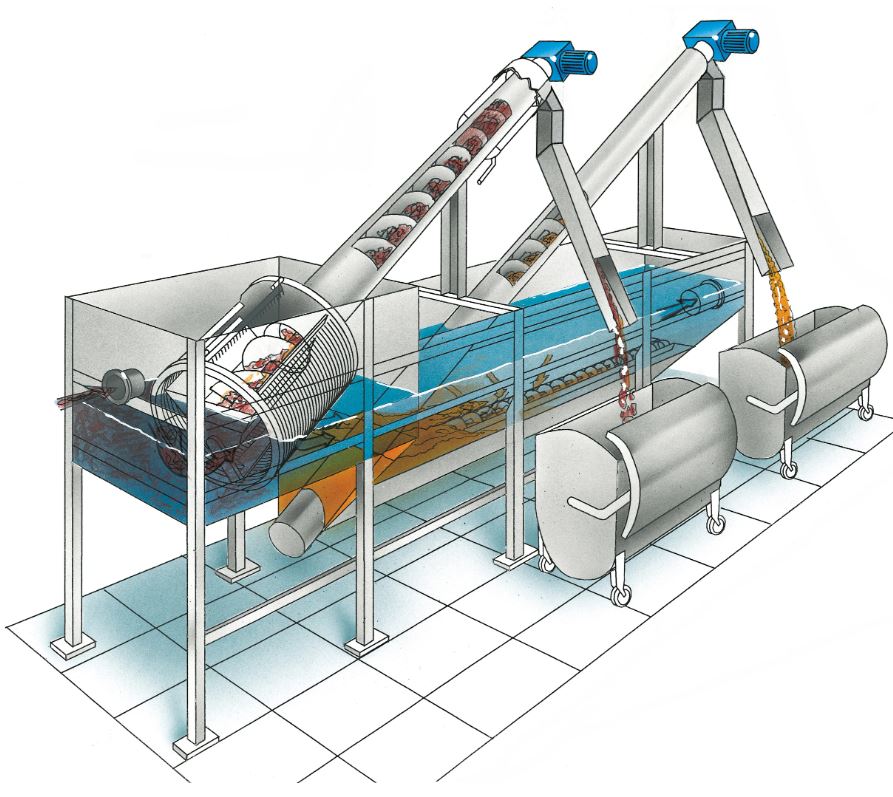

The HUBER Packaged Inlet Works System (Ro5) offers an all-in-one solution for preliminary wastewater treatment, integrating fine screening, screenings treatment, grit separation, grit discharge, fat and grease removal, and integrated grit washing into a single, compact unit. Designed for municipal STPs of all capacities, the HUBER Complete Inlet Works System ensures efficient removal of coarse solids, grit, and grease, protecting downstream processes and optimising overall plant performance.

With its modular design, the HUBER Packaged Inlet Works System Ro5 is convenient, offers high operational efficiency, and reduces maintenance requirements.

All-in-One Packaged Inlet Works Components

The HUBER Packaged Inlet Works System (Ro5) is an all-in-one solution for preliminary wastewater treatment, integrating fine screening, grit separation, grit removal, grease separation, and screenings treatment.

Fine Screening Options

The HUBER Packaged Inlet Works System offers a comprehensive selection of fine screens from the Huber range designed to meet specific site conditions such as peak flow rates, screenings load, and grit load. The available HUBER screens include:

HUBER Fine Screen ROTAMAT Ro1/Ro2 – Provides fine screening with bar spacing between 1-6 mm, effectively removing smaller solids.

HUBER Micro Strainer ROTAMAT Ro9 – Ideal for smaller plants with 1-6 mm bar spacing.

HUBER Multi-Rake Bar Screen RakeMax – Highly efficient with bar spacing from 2-10 mm, designed for high flow rates and large debris removal.

HUBER Belt Screen EscaMax – Utilises perforations ranging from 3.5-10 mm, offering high capture rates.

HUBER screens such as ROTAMAT Ro1, Ro2, and Ro9 are equipped with integrated screenings presses that dewater and compact screenings to achieve solids concentrations of up to 45% DS, eliminating the need for separate wash presses. For EscaMax screens, a HUBER Wash Press WAP is typically installed downstream, achieving solids concentrations of up to 50% DS, depending on the wash press type used.

Grit Separation Options

Grit Separation

The grit channels in HUBER ROTAMAT Ro5 units are engineered to international standards or customised as per client specifications. They are available as aerated units for enhanced grit separation through air-induced turbulence or as unaerated units depending on site requirements, such as storm/dry weather flow ratios and the necessity for additional grit treatment systems.

Grit Removal and Discharge

Collected grit is transported from the bottom of the grit channel using a horizontal screw conveyor. An inclined screw further agitates, conveys, and dewaters the grit before it is discharged into a HUBER Coanda Grit Washer RoSF4 T, which cleans and classifies the grit. An option for pumping the grit to the washer is also available for flexible system design.

Grease Separation and Removal (Optional)

In aerated grit channels, fats and grease are efficiently separated and collected in a dedicated grease chamber. The partition between the grit and grease chambers features a slotted scum board that allows floating grease to pass through, driven by aeration-generated flow. A stainless steel paddle scraper, operated via a rope mechanism, removes nearly all floating matter from the surface, preventing anaerobic degradation and odour issues.

Optional Integrated Grit Washing

Integrated grit washing systems transport separated grit directly to a washer at the plant outlet. Upwardly directed service water fluidises the grit, facilitating the separation of lighter organic particles from dense grit particles, aided by a rabble rake. The cleaned grit is then dewatered by a classifying screw and discharged into a container for disposal.

From Concept to Completion – Contact Hydroflux Epco for Packaged Inlet Screen Solutions

Packaged Inlet works treatment is a critical component of wastewater treatment, ensuring the efficient removal of solids to protect downstream processes and improve overall plant performance. Hydroflux Epco, with its extensive expertise and technical know-how, offers a comprehensive range of Packaged Inlet Works solutions designed to meet the needs of any municipality.

Our team of experts understands the complexities of screening and grit removal processes and will always provide tailored advice on selecting, designing, and optimising the correct systems in each case.

Get in touch with Hydroflux Epco today to learn how we can help streamline your wastewater treatment operations with reliable, high-performance solutions.

HUBER Ro5 Packaged Inlet Works Brochure

Please download the HUBER Ro5 Packaged Inlet Works brochure here.