Grit Separation & Handling

Efficient Grit Separation for Reliable Wastewater Treatment Performance

Hydroflux Epco provides advanced grit separation systems designed to enhance the reliability and efficiency of wastewater treatment plants. Our technologies effectively remove grit and mineral particles from wastewater while minimising the retention of degradable organic matter. Reliable grit removal plays a critical role in preventing operational issues such as sediment accumulation in aeration tanks and digesters, as well as reducing wear and tear on pumps, pipelines, and other downstream equipment.

Our comprehensive range includes Grit Classifiers, Circular Grit Traps, Vortex Grit Chambers, and Longitudinal Grit Traps—each capable of capturing inorganic particles as small as 0.20 mm. These solutions are engineered to optimise plant performance, minimise maintenance demands, and extend equipment lifespan.

Advanced Grit Separation with the HUBER Coanda Grit Classifier RoSF3

The HUBER Coanda Grit Classifier RoSF3 is designed for highly efficient grit separation, utilising density differences between grit and organic matter to reduce organic contamination while enabling static dewatering. Its advanced design allows for a significantly more compact footprint compared to conventional classifiers.

How it works

The grit-water mixture enters the vortex chamber either by pump or gravity, where a rotary motion is induced. An automatic air intake occurs through the centrally located drilling hole, enhancing the separation process.

At the core of the system is the Coanda Tulip, which ensures optimal grit classification. Incoming water adheres to the tulip wall and is redirected horizontally below the water surface, leveraging the Coanda Effect to minimise radial and tangential flows. This enhances separation by utilising density differences between organic and mineral materials.

The classifier screw then transports the cleaned grit up an inclined plane, where it undergoes gravity-driven dewatering before discharge into a skip. Under optimal conditions—such as with appropriate pre-screening and grit collection facilities—the system achieves a mineral residue purity of over 90%.

Features

- High levels of grit separation of 95 % of grain size 0.20 – 0.25 mm

- Utilisation of the Coanda effect ensures high grit removal efficiency

- Screw supported on both ends for minimised wear

- High corrosion resistance

- Encapsulated, odour-free plant

Efficient Grit Separation with the HUBER Vortex Grit Chamber VORMAX

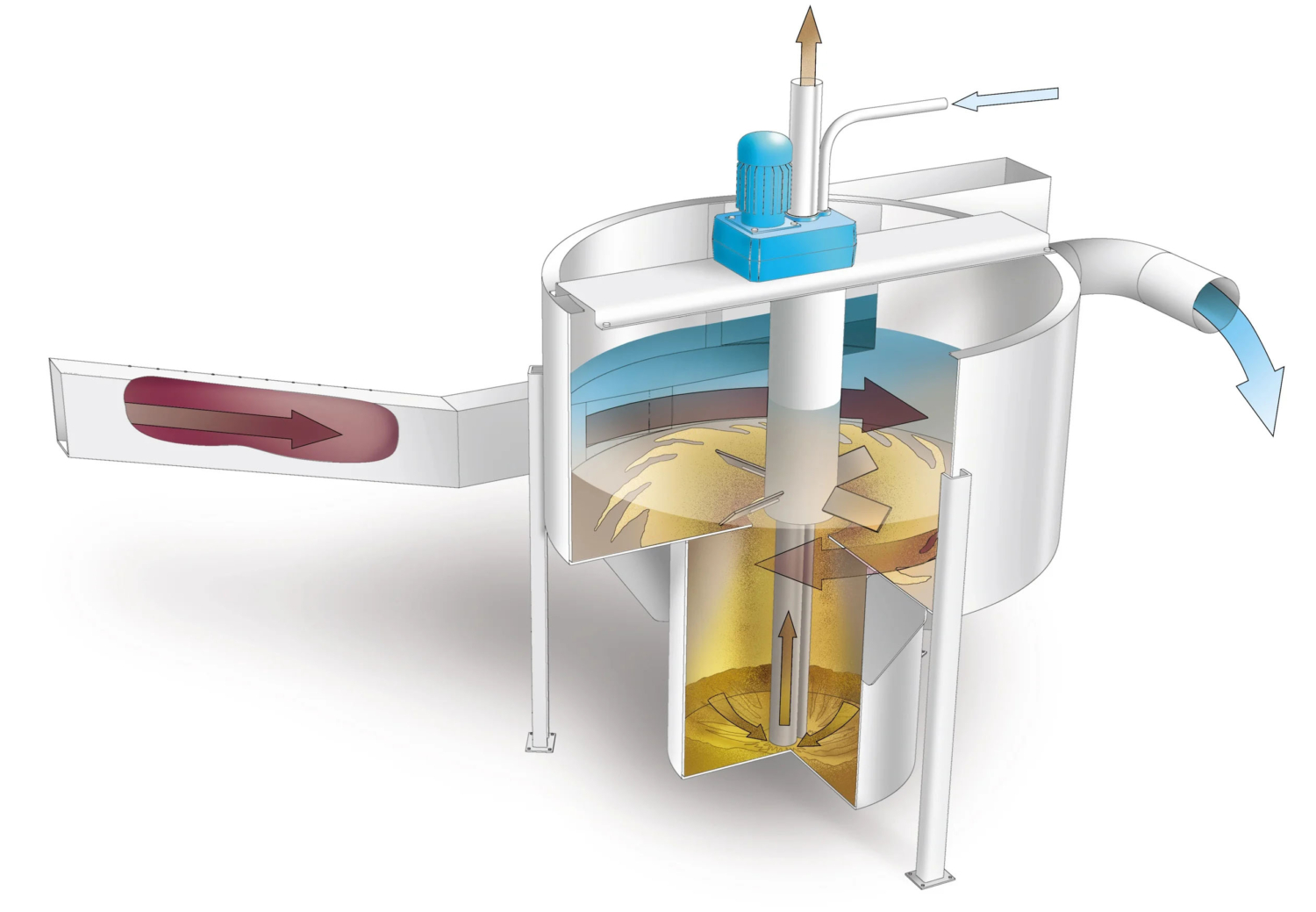

The HUBER Vortex Grit Chamber VORMAX is a compact, efficient grit removal system that uses a controlled vortex flow to separate grit, sand, and fine particles from wastewater with minimal organics carryover.

How it works

Grit separation in the HUBER Vortex Grit Chamber VORMAX begins in the inlet channel of the grit trap. Similar to an unaerated longitudinal grit trap, grit settles at the channel bottom and is transported with the wastewater flow into the circular grit chamber. The curved design of the (typically customer-constructed) concrete tank induces a tangential rotational movement, enhancing the separation process.

A continuously rotating stirrer maintains wastewater circulation, ensuring a consistent rotational velocity across the entire grit trap, even under fluctuating hydraulic conditions. The constant radial rotation generates a secondary flow near the bottom, quickly directing solids to the centre of the grit chamber. From there, grit settles into the bottom of the grit collection tank while the grit-free wastewater flows onward to the next treatment stage.

The collected solids can then be transferred via centrifugal or airlift pumps to the HUBER RoSF3 Grit Classifier to undergo separation, dewatering, and removal of organic particles for optimal processing.

Features

- Compact, space saving design with high grit separation efficiency

- Throughput capacity up to 3,000 l/s (10,800 m³/h)

- Low energy demand

- Variable inlet and outlet arrangement

- Minimum wear, reduced maintenance

Optimised Grit Separation with the HUBER Circular Grit Trap HRSF

How it works

The HUBER Circular Grit Trap HRSF enhances grit separation through the rotational motion of wastewater. This process creates a separation effect by combining a vertical downward flow with centrifugal force, efficiently directing grit particles toward the inner tank surface, which serves as the primary separation area.

To maximise performance, the HRSF is equipped with an additional separation cone, increasing the effective separation area and ensuring highly reliable grit removal.

For improved organic separation, an optional aeration system can be integrated. The introduction of air keeps organic matter suspended, allowing it to be carried away with the water flow above the separator cone while the grit settles below.

Separated solids can be discharged either directly via an integrated classifying screw or pumped into a grit classifier for further processing.

The HUBER Circular Grit Trap HRSF was developed using advanced numerical design engineering and has been rigorously tested and validated under real-world conditions in collaboration with the German test institute LGA.

Features

- Maximum separation efficiency due to additional separation area (separator cone)

- Throughput capacity up to 150 l/s (540 m³/h)

- Compact, space-saving unit

- Encapsulated, odour-free plant

- Completely made of stainless steel for high corrosion resistance

- Optional with integrated grit classifying screw, scum separator and aeration

Comprehensive Grit Separation and Removal with the HUBER Longitudinal Grit Trap ROTAMAT® Ro6

The HUBER Longitudinal Grit Trap ROTAMAT® Ro6 is a space-saving, high-efficiency system that removes grit, sand, and other heavy particles from wastewater using a horizontal flow channel with integrated grit washing.

The HUBER Longitudinal Grit Trap ROTAMAT® Ro6 is designed in compliance with DWA recommendations or customised to meet specific customer requirements. Available in both aerated and unaerated versions, the selection depends on factors such as the ratio between storm and dry weather flow and the presence of downstream grit treatment facilities. The system efficiently separates grit, which is transported via a horizontal conveyor to an inclined grit removal screw. This screw dewaters and compacts the grit before discharging it into a container or directing it to a HUBER Coanda Grit Washer RoSF4 T for further treatment. If required, the separated material can also be pumped to an external grit washer.

For aerated grit traps, grease and fat separation is an additional feature. The aeration system generates a flow that transports grease through a slotted scum board into a separate grease chamber. Unlike many competitor systems, the HUBER Longitudinal Grit Trap ROTAMAT® Ro6 includes a forced grease transport mechanism, using a grease removal paddle with a guided scraper to ensure complete removal along the entire grit trap length. This prevents anaerobic digestion and associated operational issues. Additionally, an integrated grit washer can be installed at the plant outlet, where upwardly directed service water fluidises the grit to separate lighter organic particles. A rabble rake further enhances separation before the clean grit is conveyed by a classifying screw, statically dewatered, and discharged into a container for disposal or reuse.

From Design to Delivery – Contact Hydroflux Epco for Tailored Grit Separation Solutions

Effective grit removal is critical to the performance and longevity of wastewater treatment infrastructure. At Hydroflux Epco, we deliver customised grit separation solutions that are engineered to integrate seamlessly into both new and existing treatment plants.

Our experienced team works closely with clients from concept through to commissioning, providing detailed design documentation and ensuring efficient handling, classification, and disposal of separated grit in full compliance with regulatory standards. With proven expertise and industry-leading technologies, Hydroflux Epco supports you in selecting and optimising the right grit separation systems to protect your downstream processes and reduce maintenance.

Contact us today to discover how our grit separation solutions can enhance the reliability and efficiency of your treatment plant.

HUBER Grit Classifier and Separator Brochures

Please download the brochure here.