Biogas Equipment

Reliable and Sustainable Biogas Handling Equipment

Hydroflux Epco provides advanced biogas equipment designed to optimise the capture, treatment, and utilisation of biogas from the anaerobic treatment of wastewater and organic waste treatment processes. Our solutions support industries in reducing carbon emissions, generating renewable energy, and enhancing operational efficiency.

Industry-Leading Technology & Global Partnerships

In addition to our proprietary technologies, Hydroflux Epco partners with Baur Folien GmbH and Gastechnik Himmel, leading European experts in biogas storage, treatment, and utilisation. Together, we offer high-performance solutions tailored to the New Zealand market.

Why Businesses Choose Hydroflux Epco?

Sustainable & Cost-Effective – Maximises energy recovery while reducing carbon footprint.

Proven Technology – Proprietary technology and engineering backed by global leaders Baur Folien GmbH and Himmel.

Custom Engineered Solutions – Tailored to specific site and process requirements.

Regulatory Compliance – Meeting New Zealand and international environmental standards.

Choosing Hydroflux Epco means selecting a trusted partner that combines high-quality systems, specialised equipment, and deep industry expertise to deliver outstanding biogas equipment and handling solutions.

Hydroflux Epco’s Biogas Equipment & Solutions

Hydroflux Epco offers a comprehensive range of biogas equipment and solutions designed to maximise energy recovery, enhance safety, and improve biogas quality, ensuring efficient and sustainable utilisation of biogas in wastewater and organic waste treatment processes.

Biogas Holders & Storage Systems – High-performance double-membrane gas storage solutions designed for reliability and longevity.

Biogas Desulfurisation & Treatment – Removal of H₂S and contaminants to improve biogas quality and protect energy recovery systems.

Biogas Flares & Safety Systems – Ensuring safe combustion and controlled disposal of excess biogas when necessary.

Efficient and Reliable Biogas Buffering for Optimal Utilisation

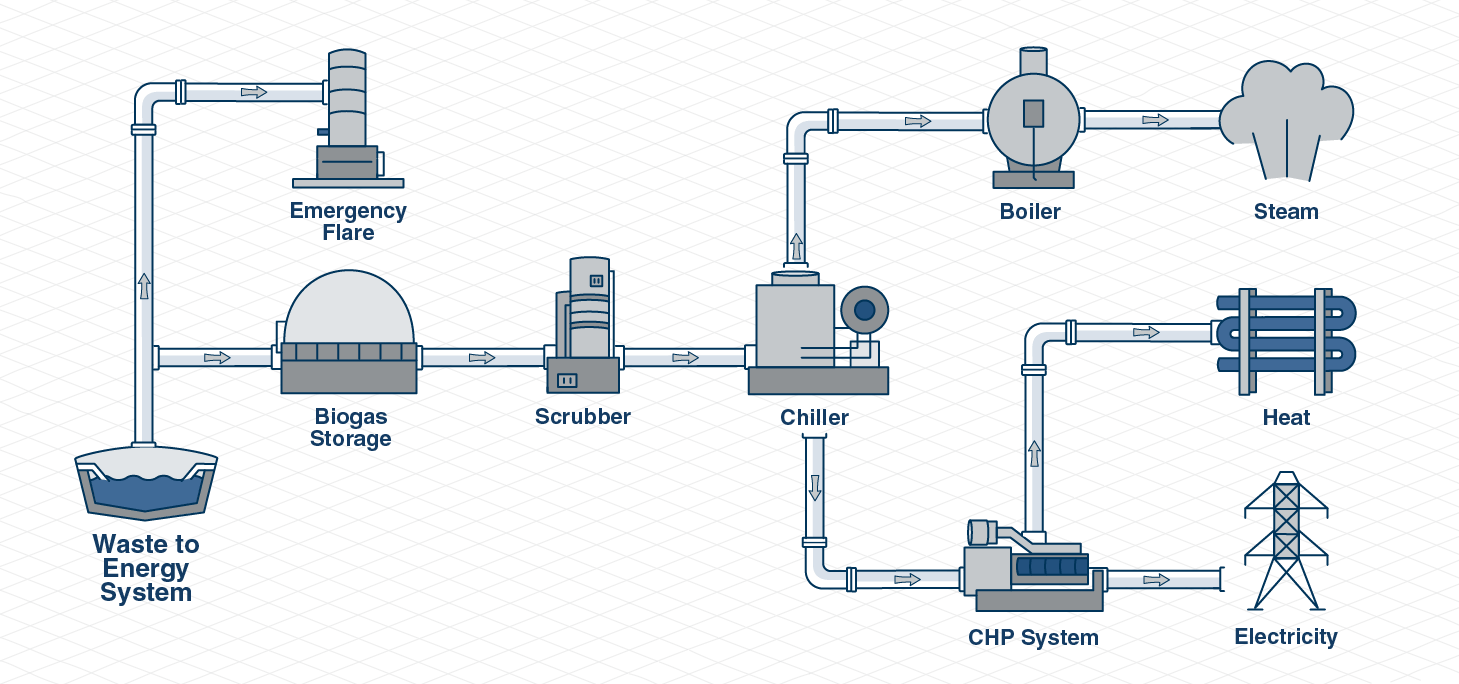

In anaerobic digestion and wastewater treatment processes, intermediate storage of biogas is essential to balance variations between production and consumption, ensuring a stable and continuous supply to downstream combustion devices such as boilers and Combined Heat and Power (CHP) systems. Since biogas production rates can fluctuate due to process conditions, while energy systems require a steady and controlled gas supply, an efficient storage solution is critical for maximising energy recovery and operational efficiency.

Hydroflux Epco provides high-performance biogas storage systems designed to accommodate these fluctuations, offering safe, durable, and customisable solutions tailored to various plant capacities and operational requirements.

Hydroflux Epco Biogas Storage Solutions

Flexible & Scalable Designs – Available in multiple configurations, including low-pressure and high-pressure storage, to match specific process needs

Double-Membrane Gas Holders – Utilizing high-strength, UV-resistant, and gas-tight membranes from Baur Folien GmbH, ensuring long-term durability and performance

Optimised Gas Flow Regulation – Integrated pressure control and gas regulation mechanisms to smooth out variations between production and usage

Compact & Space-Efficient Solutions – Suitable for both new installations and retrofits, allowing easy integration into existing infrastructure

Safe & Compliant – Designed to meet New Zealand safety standards and environmental regulations, ensuring gas-tight storage and controlled release

Hydroflux Epco Biogas Flares and Safety Systems – Ensuring Safe and Controlled Biogas Management

Biogas flaring is a critical safety and environmental control measure for managing excess or unutilised biogas in wastewater treatment plants, anaerobic digestion facilities, and landfill gas systems. Proper flaring ensures that methane and other combustible gases are safely combusted, reducing greenhouse gas emissions and preventing the release of harmful contaminants into the atmosphere.

Hydroflux Epco Biogas Flare Solutions

Hydroflux Epco provides high-efficiency, low-emission biogas flaring systems designed for safe, controlled, and regulatory-compliant operation. Our flares are engineered to handle variable gas flow rates while ensuring complete combustion and minimal environmental impact.

- Open and Enclosed Biogas Flares

• Open flares provide a cost-effective solution for safely combusting biogas in non-sensitive environments

• Enclosed flares feature high-temperature combustion chambers to ensure low emissions and compliance with stringent air quality standards - Automatic Ignition and Monitoring

• Self-igniting pilot systems ensure reliable flare operation, even in fluctuating gas flow conditions

• Gas flow and temperature monitoring allow real-time tracking and automatic shutdown in case of system irregularities - Low-NOx and High-Efficiency Combustion

• Designed to achieve complete combustion of methane and hydrogen sulfide, minimizing NOx and SOx emissions

• Adjustable combustion controls optimize performance based on biogas composition

Hydroflux Epco Biogas Desulfurisation and Treatment Solutions

Biogas generated from anaerobic digestion often contains contaminants such as hydrogen sulfide (H₂S), moisture, and siloxanes, which can corrode equipment, reduce energy efficiency, and increase maintenance costs. Effective biogas desulfurisation and treatment are essential to protect combustion engines, boilers, and CHP systems, ensuring a cleaner and more efficient fuel source.

Hydroflux Epco Biogas Treatment Solutions

Hydroflux Epco offers a complete range of biogas purification technologies, tailored to specific site and process requirements, including:

- H₂S Removal Systems

• Biological Desulfurisation – Uses naturally occurring sulfur-oxidising bacteria to convert H₂S into elemental sulfur, providing a low-cost and eco-friendly solution

• Chemical Scrubbing – Removes H₂S using alkaline or iron-based scrubbing systems, ensuring efficient gas purification

• Activated Carbon Filtration – Adsorption technology for removing H₂S, VOCs, and siloxanes, extending the lifespan of CHP engines and turbines - Biogas Dehumidification & Moisture Removal

• Gas Cooling & Condensation Systems – Lowers the dew point of biogas, allowing moisture to be separated and drained

• Siloxane & VOC Removal – Prevents deposits that can damage turbines and CHP engines, ensuring long-term performance - Biogas Safety & Monitoring Systems

• Gas Analyzers & Online Monitoring – Continuous tracking of H₂S levels, CH₄ content, and gas flow for process optimisation

• Gas Pressure & Flow Control – Regulating gas flow to protect downstream energy recovery equipment

Contact us for your Complete Biogas Project Delivery

Hydroflux Epco provides a full-service approach to biogas equipment and system delivery, from concept design through to installation, commissioning, and ongoing support. With a team of experienced civil, mechanical, chemical, and electrical engineers supported by project managers, site supervisors, commissioning specialists, and service technicians, we ensure seamless project execution and long-term performance.

- Nationwide Support – Local teams across New Zealand for fast, reliable service

- Turnkey Solutions – From design and procurement to construction and commissioning

- Flexible Delivery – Equipment supply only, or full EPC contracts

- Detailed Design Support – Including PFDs, equipment layouts, integration with existing infrastructure

- Regulatory & Environmental Compliance – Designed to meet New Zealand standards

- Ongoing Service – Post-installation maintenance contracts to ensure lasting performance

Our experts work closely with clients, contractors, and consultants to deliver tailored biogas handling and treatment solutions. Whether upgrading an existing facility or building a new plant, we provide trusted guidance every step of the way.

Get in touch with Hydroflux Epco today.