Conveyors and Silos

Robust Conveyors for Municipal Sludge

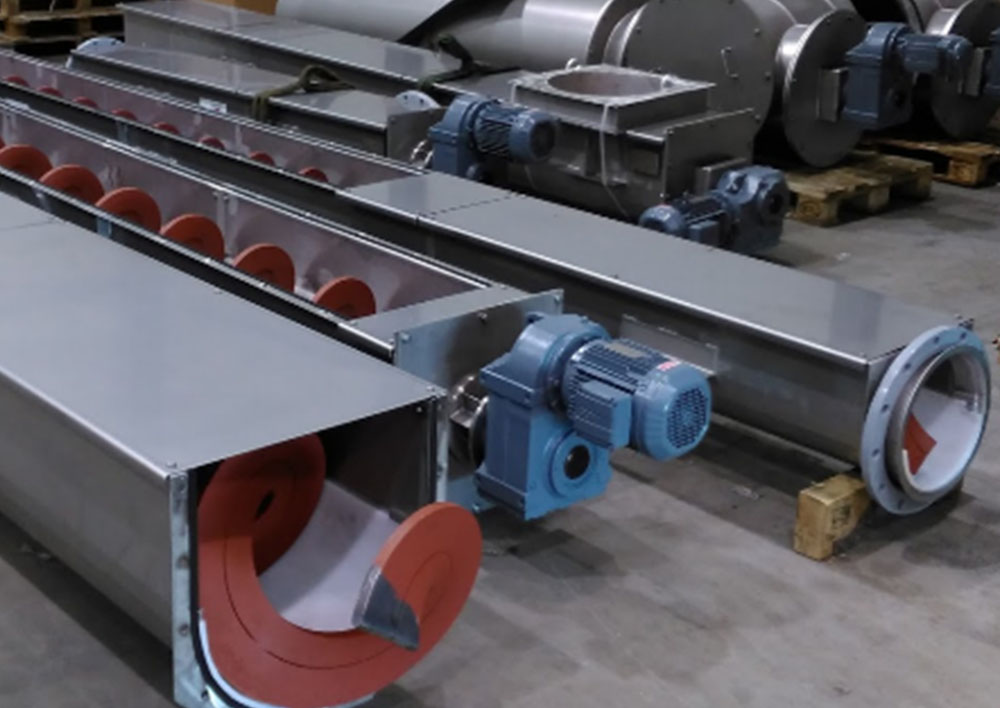

Hydroflux Epco is proud to partner with Dutch Spiral, a globally recognised leader in the design and manufacture of shaftless screw conveyors. With decades of expertise, Dutch Spiral provides high-quality, custom-engineered solutions for transporting dewatered sludge, screenings, grit, and other challenging materials in wastewater and industrial applications.

Our collaboration ensures that New Zealand industries benefit from proven, efficient, and durable conveying solutions tailored to their specific needs. Dutch Spiral’s advanced shaftless screw conveyors, combined with Hydroflux Epco’s extensive experience in wastewater and biosolids management, offer seamless integration into treatment plants, improving reliability and operational efficiency.

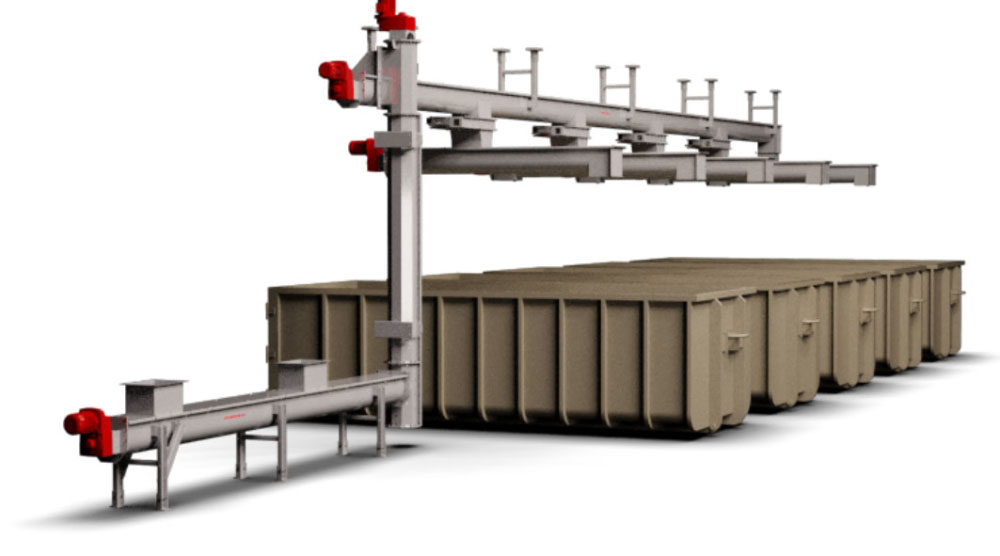

Horizontal, Inclined and Vertical Conveying

Dutch Spiral’s shaftless screw conveyors—available in horizontal, inclined, and vertical configurations—provide efficient, clog-free transport of sludge, screenings, and grit, with a customisable design that optimises space and minimises maintenance.

Shaftless Screw Conveyors

- Designed to handle sticky, fibrous, and high-moisture materials without clogging

- Ideal for transporting dewatered sludge, screenings, and grit

- Eliminates the need for intermediate bearings, reducing maintenance

Inclined Screw Conveyors

- Customisable for various angles, optimising space usage in compact treatment plants

- Ensures efficient material transport even at steep inclines

Horizontal Screw Conveyors

- Suitable for long-distance transport of sludge and solids

- Can be installed with multiple inlets and outlets to fit plant layouts

Benefits of Dutch Spiral Conveyors

High Efficiency – Engineered for smooth and reliable material transport with minimal energy consumption.

Low Maintenance – Shaftless design reduces wear and eliminates the need for internal bearings.

Customisable Solutions – Available in various sizes, lengths, and configurations to suit specific plant requirements.

Corrosion-Resistant Materials – Constructed from high-quality stainless steel for long-term durability in harsh environments.

Seamless Integration – Designed to work with Hydroflux Epco’s wastewater treatment and biosolids processing systems for optimised plant operations.

Reduced Blockages – The Shaftless design prevents clogging, making it ideal for materials with high solids content.

Trough Liners for Dutch Spiral Shaftless Screw Conveyors

Trough liners are a critical component of Dutch Spiral’s shaftless screw conveyors, providing durability, wear resistance, and smooth material transport. These liners protect the conveyor trough from abrasion and reduce friction, ensuring efficient movement of sludge, screenings, grit, and other challenging materials in wastewater treatment and industrial applications.

Types of Trough Liners

UHMW-PE (Ultra-High Molecular Weight Polyethylene) Liners

- High wear resistance for extended service life

- Low friction for smooth material flow and reduced energy consumption

- The non-stick surface minimises material buildup and blockages

Ceramic-Reinforced Liners

- Designed for highly abrasive materials like grit and sand

- Superior hardness and impact resistance for extended durability

Stainless Steel Liners

- Used in high-temperature or corrosive environments

- Provides extra rigidity for heavy-duty applications

Contact Hydroflux Epco for an Initial Technical Discussion

The conveying of sludge and solids is a critical component of any wastewater treatment plant, and Hydroflux Epco, with its extensive expertise and technical know-how, offers a comprehensive range of conveying solutions designed to meet the needs of any municipality.

Our team of experts understands the complexities of conveyors and will always provide tailored advice on selecting, designing, and optimising the correct conveying systems in each case.

Get in touch with Hydroflux Epco today to learn how we can help streamline your wastewater treatment operations with reliable, high-performance conveying solutions.

Dutch Spiral Brochures

Please download the Dutch Spiral brochures here.