RoadTrain® Packaged Wastewater Treatment Plants

Robust and Reliable Packaged Wastewater Treatment Plants

The RoadTrain® packaged wastewater treatment plant is designed for remote applications, offering scalable capacities from 60 to 1,000 EP per train, with the flexibility to accommodate larger flows through a modular configuration. Engineered for minimal on-site attendance, the system features built-in redundancy and a robust, reliable design to ensure continuous and efficient operation.

The optimal process selection is determined based on site footprint, location constraints, and discharge or reuse requirements, ensuring a tailored solution for each application. With a proven track record dating back to the late 1960s, Hydroflux Epco’s RoadTrain packaged wastewater treatment plants have been successfully deployed in various remote and decentralised locations, demonstrating long-term reliability and performance.

Applications include sewage treatment for:

- Towns, villages and communities

- Resorts, hotels and leisure complexes

- Mine sites and gas exploration fields

Browse the RoadTrain photo gallery.

Features

The RoadTrain is a proven and robust packaged wastewater treatment solution designed for remote, sensitive, and challenging environments.

- Proven in sewage treatment applications in remote locations within several countries

- Built-in process redundancy

- Modular configuration

- Mechanical robust & reliable design – installations from the early 1970s are still in operation

- Unique aeration cycling to maximise nitrification and de-nitrification

- Tertiary filtration can be added to provide Class A and A+ water

- Proven in environmentally sensitive areas such as the Great Barrier Reef and Torres Straits

- Pre-fabricated systems to reduce site installation time

- Optional bolted designs where there is no or limited access

RoadTrain Configurations

RoadTrain packaged plants are available in an Extended Aeration Activated Sludge Process, which is the most common, but also in Modified Ludzack Ettinger (MLE) Process, Rotating Biological Contactor (RBC), Moving Bed Biofilm Reactor (MBBR) & Membrane Bioreactor (MBR) configurations. All models are available in a fully welded or “bolt-on site version”.

The RoadTrain product range suits various site & effluent requirements with typical applications below:

| Model | Process | Applications |

| RoadTrain® Original | Intermittent activated sludge process | Remote sites, without biological nitrogen removal |

| RoadTrain® Advanced | MLE process | Remote, environmentally sensitive sites with tighter TN targets of 5 – 15 mg/L. |

| RoadTrain® Ultra | Membrane Bioreactor | To produce Class A discharge for environmental discharge or reuse |

| RoadTrain® Plus | Moving Bed BioFilm | For capacities >150 kL/d and where a long design life is required or ror process intensification of existing systems |

| RoadTrain® RBC | Rotating Biological Contactor | Remote sites with little operator attention, up to 150 kL/d and a TN limit of 15 mg/L |

| RoadTrain® SBR | Sequential Batch Reactor | Remote sites with a tighter nitrogen target |

Bolt-On Site v Fully Assembled

The key difference between a bolted (on-site assembled) RoadTrain system and a fully assembled RoadTrain system lies in their installation method, site requirements, and logistics. For the bolted version, assembly is typically carried out by local site crews with supervision of installation by Hydroflux Epco, whilst the fully assembled version has a very high level of offsite fabrication, assembly and works testing, minimising site works. Both configurations maintain the same process performance, modular flexibility, and robust design, ensuring reliable wastewater treatment in diverse environmental and operational conditions.

Bolted (On-Site Assembled) RoadTrain® System

- Delivered as flat-packed components and assembled on-site

- Suitable for remote or constrained sites where transporting large pre-assembled units is not feasible

- Offers greater flexibility for installation in areas with limited access or where large cranes and heavy transport vehicles cannot be used

- Takes longer to install compared to a fully assembled system but provides a custom-fit solution for difficult locations

- Assembly can be carried out by local site crews

Fully Assembled RoadTrain® System

- Pre-fabricated, ensuring faster installation.

- Ideal for locations with good site access where large transportable units can be delivered.

- Reduces on-site construction time

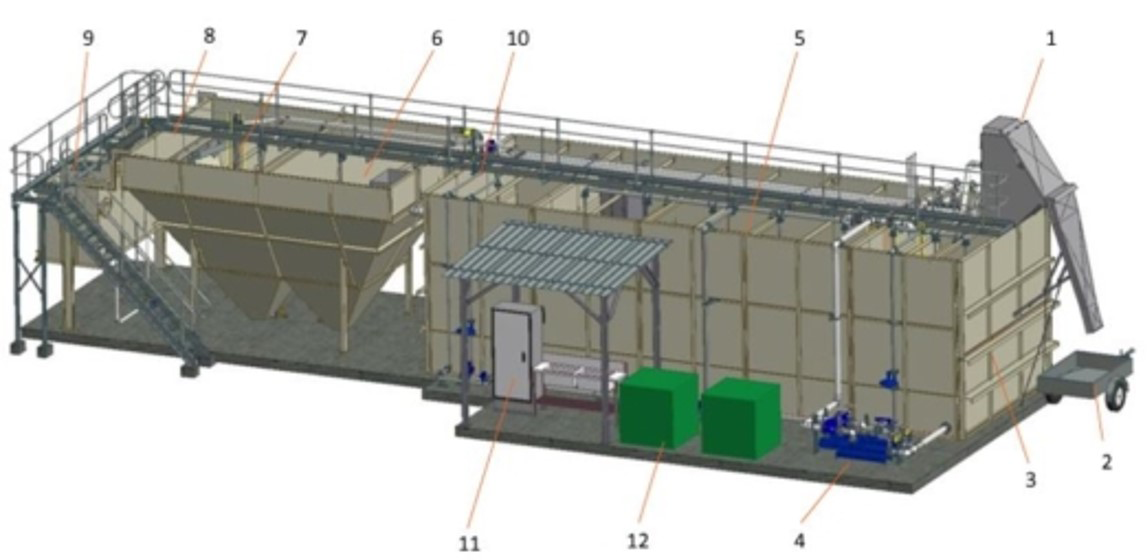

RoadTrain Original – Typical Components

- Inlet Screen: Mechanical or manual inlet screen removing solids.

- Screenings Bin: Typically, skip or wheelie bins, based on site conditions.

- Balance Tank: Provides flow equalisation and manages variable inflow.

- Forward Flow Pumps: Transfers screened and balanced wastewater into the biological treatment zones.

- Aeration Tank: Primary biological treatment zone, delivering oxygen via Hydroflux Epco coarse or fine bubble diffusers.

- Clarifier: Allows sludge to settle from the treated water.

- Sludge & Scum Returns: Via pump or air lift, RAS (Return Activated Sludge) is sent back to the aeration tank and WAS (Waste Activated Sludge) to sludge tank.

- Effluent Trough: collects clarified effluent from the clarifier, channelling the flow to the disinfection stage.

- Chlorine Detention Tank: disinfection stage to reduce pathogens, designed to provide sufficient contact time for chlorination.

- Waste Activated Sludge Tank: Temporarily stores excess WAS for either further dewatering or periodically pumped out.

- Control Panel: Houses all electrical and control systems to operate the RoadTrain, can include HMI and remote monitoring.

- Blowers: Supplies air to the diffusers within the aeration tank.

RoadTrain – Reliable & Scalable Wastewater Treatment for Remote Sites

The Hydroflux Epco RoadTrain Packaged Wastewater Treatment Plant is a robust and scalable solution designed for remote communities, mining camps, and temporary sites requiring reliable wastewater treatment. Engineered for high efficiency, ease of deployment, and minimal operational oversight, the Roadtrain system ensures compliance with environmental regulations while delivering superior treatment performance.

With modular configurations, advanced biological treatment processes, and durable construction, Hydroflux Epco Roadtrain plants provide a sustainable and cost-effective approach to wastewater management. Whether for a shorter-term project or a long-term remote installation, Hydroflux Epco’s expertise ensures optimal performance and support.

For more information or to discuss a tailored solution, contact Hydroflux Epco today.

Downloads

Download the brochure and technical information on RoadTrain here