HUBER GritWolf – Setting The Highest Standards for Grit Removal Efficiency

May 30, 2019

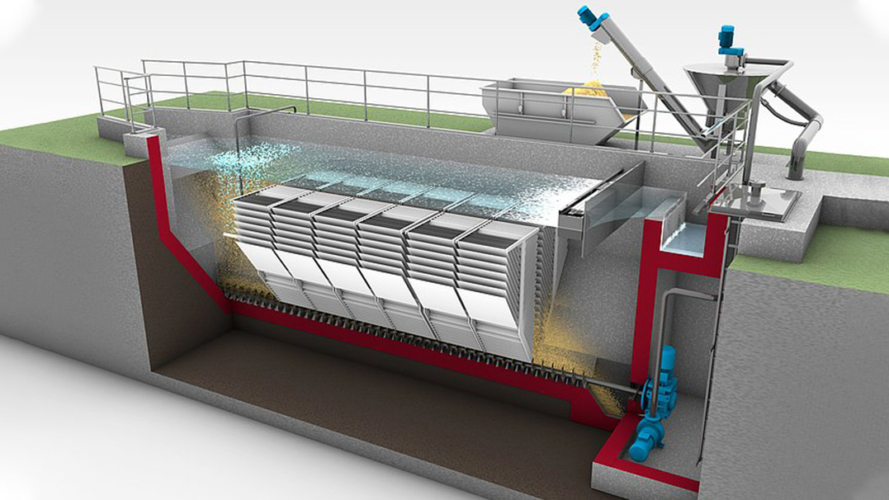

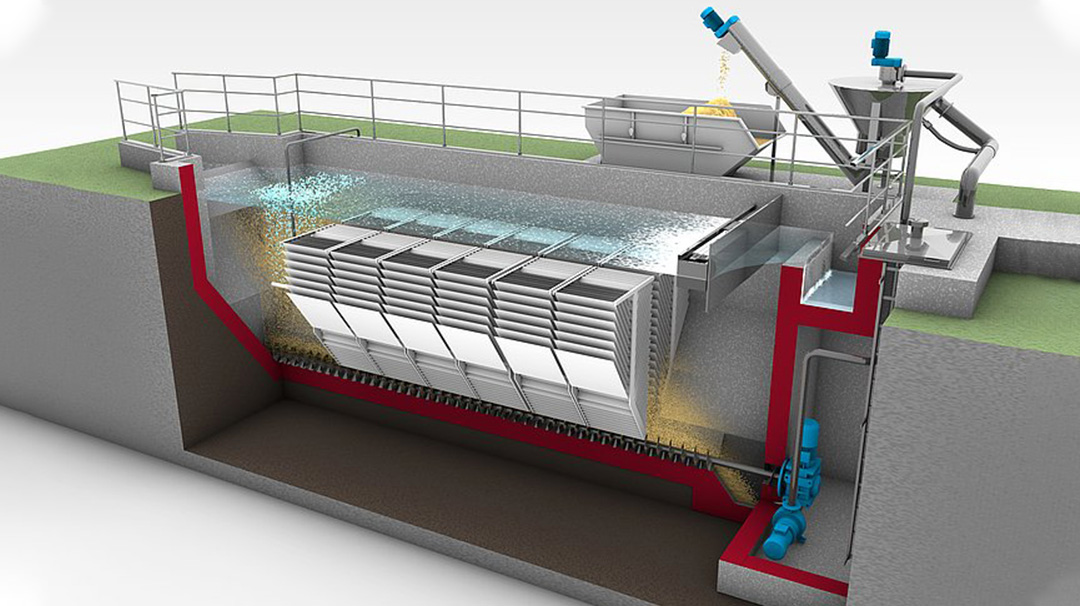

GritWolf is a hybrid grit removal system that combines aerated and un-aerated zones to achieve grease removal and the removal of ultra-fine grit particles with a particle size of >75micron.

Key Advantages of the system include:

Key Advantages of the system include:

- 95% Removal of >75 micron grit particles

- Integrated grease removal

- Compact footprint

- Low headloss

- Stainless steel internals

The first zone allows for flotation and removal of grease, something that is not possible within a vortex grit trap. The second zone is fitted with lamella plates that provide a high surface area for separation of these ultra-fine grit particles.

Sizes are available from 44 L/s through to 850L/s in a single system. For flows up to 175L/s the system can be provided within a pre-fabricated stainless steel tank, which reduces site construction costs. For flows greater than 175L/s a concrete channel is more economical and the GritWolf is then installed within this concrete chamber.

The HUBER GritWolf® can also be integrated into existing grit trap chambers. The horizontal grit conveyor, the lamella packages and the paddle system for grease removal are manufactured from stainless steel.

For more information please click here.

Up Next

So Simple, So Efficient.

Hydroflux Group Newsletter – May 2019

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement