Plate Wastewater Heat Exchanger

Wastewater contains thermal energy which can be recovered. The HUBER ThermWin® system is designed to withdraw sewage from the sewer, screen it, pump it through above-ground Heat Exchangers to recover the energy, and then return it back into the sewer.

Because our Heat Exchanger will be installed above-ground instead of a direct sewer installation, there are several benefits regarding installation and maintenance effort.

Due to the modular design the Heat Exchanger can be customized for any project size. Dependant on it’s size, this system may generate some hundreds kilowatts of “green” heating power in connection with a heat pump.

Find out more

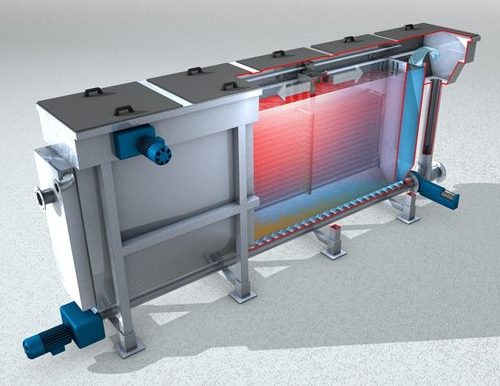

The HUBER RoWin Heat Exchanger consists of a welded stainless steel construction in which horizontal pipe modules are arranged in parallel. The pipe modules are made of stainless steel to achieve maximum heat transfer efficiency. The pre-screened wastewater flows through the heat exchanger and, via the compactly arranged pipes, gives off its thermal energy to the cooling water.

The energy for the heat pump is supplied through the heated cooling medium. Due to the specific chemical biological properties of wastewater a biofilm is developed overtime on the heat transfer surfaces that significantly impairs heat transfer. Preventive cleaning of the heat transfer surfaces therefore is applied to ensure the maximum heat transfer capacity is permanently maintained. Sediments and solids settling on the tank floor are removed by a screw conveyor and returned to the sewer along with the cooled wastewater. Due to the enclosed tank design and return of solids thermal energy is the only emission from wastewater.

The HUBER RoWin Heat Exchanger is available, as required, with an outer insulation for particularly exposed sites. Installed above ground, the system offers the benefits of easy maintenance and operation. Due to its modular design the HUBER RoWin Heat Exchanger can be tailored to suit specific site requirements. In combination with a heat pump up to several hundred kilowatts of thermal output can be generated, depending on the units size. With the optimal combination of both systems municipalities or industrial enterprises can cover up to 80 % of the heat required from wastewater as energy source.

The HUBER RoWinB Heat Exchanger can be used for installation in the outlet of the wastewater treatment plant or in buffer tanks. Installed directly in the wastewater flow, the heat exchanger modules are optimally surrounded by the flow. Due to the biological processes taking place, the temperature of effluents from sewage treatment plants is on average by 1 K higher than the inlet temperature. Furthermore, higher amounts of thermal energy can be extracted from WWTP effluents than with heat recovery plants installed in sewer systems. The biological processes in the sewage treatment plant are not impaired and the introduction of the cool WWTP effluent outlet is beneficial for the flowing water biology.

In addition, temperature and oxygen conditions in the waters are significantly improved. If installed in the channel, no additional pumps are required as the wastewater flow normally runs off by gravity. This avoids costs and significantly improves the economic efficiency of such plants

Due to its compact design and installation in a channel or tank, no additional installation space is required and the available space utilised at an optimum. But biofilm growing on the heat exchanger surfaces cannot completely be ruled out with the use of the WWTP effluent. Integrated cleaning of the heat transfer surfaces therefore is of great importance to continuously maintain the maximum heat transfer capacity. Several HUBER RoWin Heat Exchanger units can be installed in parallel or in series for perfect adjustment to specific site conditions and customer requirements. Combined with load-bearing covers the units can also be installed under parking areas for example.

- Compact, enclosed tank design

- Continuous maximum heat transfer capacity

- Stable hydraulic conditions

- Fully automatic operation, minimum maintenance requirements

- Unsusceptible to grease, floating and coarse material

- Automatic removal of sediments

- Modular design for tailored solutions that meet the customer’s specific requirements

- Various possible applications in both the municipal and industrial field