Inclined Drum Screens

The ROTAMAT® Inclined Drum Screen Ro2 is part of a range of high quality German manufactured screens designed specifically to process wastewater with high levels of solids and gross material.

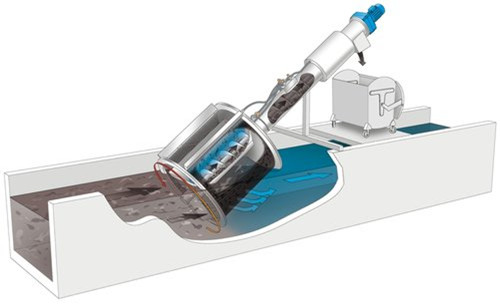

The ROTAMAT® Rotary Drum Fine Screen Ro2 is a reliable and well-proven inlet screen for municipal sewage treatment plants, industrial wastewater and process water screening. Its operation is based upon a unique system that also allows a combination of screening, washing, transport, compaction and dewatering in a single unit.

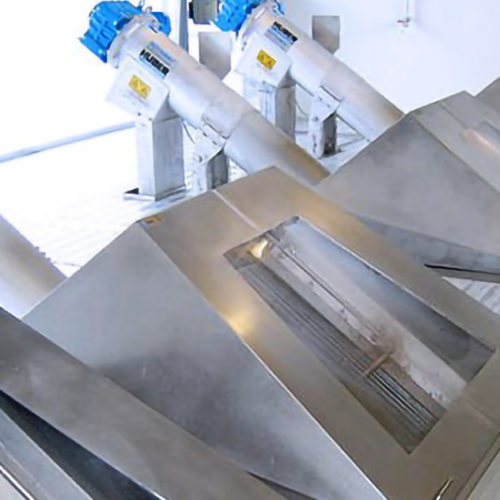

The screening elements can be either wedge wire spaced at 0.5-6mm, or 1-6mm perforated drums. Depending on the aperture size selected and the screen diameter (screen basket diameter of up to 3000 mm are available),the throughput can be individually adjusted to specific site requirements.

The ROTAMAT® Rotary Drum Fine Screen is completely made of stainless steel and can be installed either directly in the channel or in a separate tank.

Find out more

Due to the drum’s shape and 35° inclination the screen area is much greater than that of a vertical screen, which results in a low head loss, high separation efficiency and maximum throughput.

The ROTAMAT® Screens perform the functions of screenings removal, transport, washing, dewatering and compaction in a single compact unit. An optional bagging unit minimises odour.

The entire flow enters the screen drum internally and can only exit the drum through its screen area. This prevents plant overflow and guarantees that the screenings are always retained within the screen drum.

The design of the ROTAMAT® Screens allows for later modification so that the systems can be adapted to changing requirements. The heating and/or integrated screenings washing can be retrofitted. The bar spacing can also be reduced to meet more stringent requirements.

ROTAMAT® Inclined Drum Screens are either installed directly into the channels, or are supplied as free standing tank packages. The wastewater flows into the open end of the inclined screen basket and then through the screen.

Floating and suspended materials are retained by the screen basket and the blinding of the screen surface generates an additional filtering effect so that solids far smaller than the bar spacing or perforation can be retained.

The basket rotates when a preset upstream water level is exceeded. The rotating drum then lifts the screenings and discharges them into the central trough. Screenings removal is achieved by a scraper brush and a spray nozzle bar.

A screw conveyor in the trough rotates with the drum and transports the screenings through a inclined closed pipe section. The conveying screw transports, dewaters and compacts the screenings, without any odour issues, and discharges them into them a suitable container or conveying system.

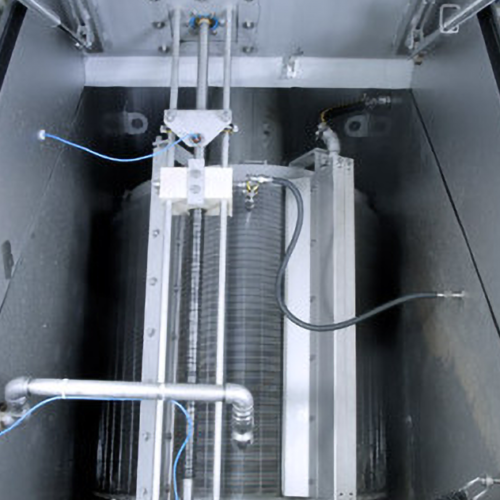

To optimise the treatment process an integrated screenings washing system IRGA can be provided. It improves the carbon/nitrogen ratio of the pre-treated wastewater whilst reducing the cost of screenings disposal.

The ROTAMAT® Ro2 allows for integration of the screenings washing system directly in the trough and/or the lower end of the rising screw. As the soluble matter is separated from the inert material, faeces are washed out which leads to a significant weight reduction.

Benefits of screenings washing

- Easy retrofit

- Minimised disposal costs for screenings

- Improved operating and hygienic conditions

- Virtually complete wash out of faeces

- Weight reduction by approx. .50%

- Dewatering performance of up to 40%DS

- The benefits of the ROTAMAT® Rotary Drum Fine Screen at a glance:

- Low head loss and very High separation efficiency

- Completely made of stainless steel

- No by-passing possible

- Low maintenance